In recent years, the international market has witnessed a significant growth in the demand for high-quality sesame oil. According to market research, the global sesame oil market is expected to grow at a CAGR of 5% from 2024 to 2030. This growth is driven by the increasing consumer awareness of the health benefits of sesame oil, such as its high content of antioxidants and anti - inflammatory properties. In addition, the growing popularity of Asian cuisine worldwide has also contributed to the rising demand for sesame oil as a key ingredient.

The sesame oil production line is equipped with advanced core technologies and a strict quality control system. For example, the use of state - of - the - art extraction technology can achieve an extraction rate of up to 90%, which is much higher than the industry average of 80%. The quality control system includes multiple inspection points throughout the production process. Every batch of raw sesame seeds is tested for purity, moisture content, and oil content. During the production process, parameters such as temperature, pressure, and extraction time are precisely controlled to ensure the consistency and high quality of the final product.

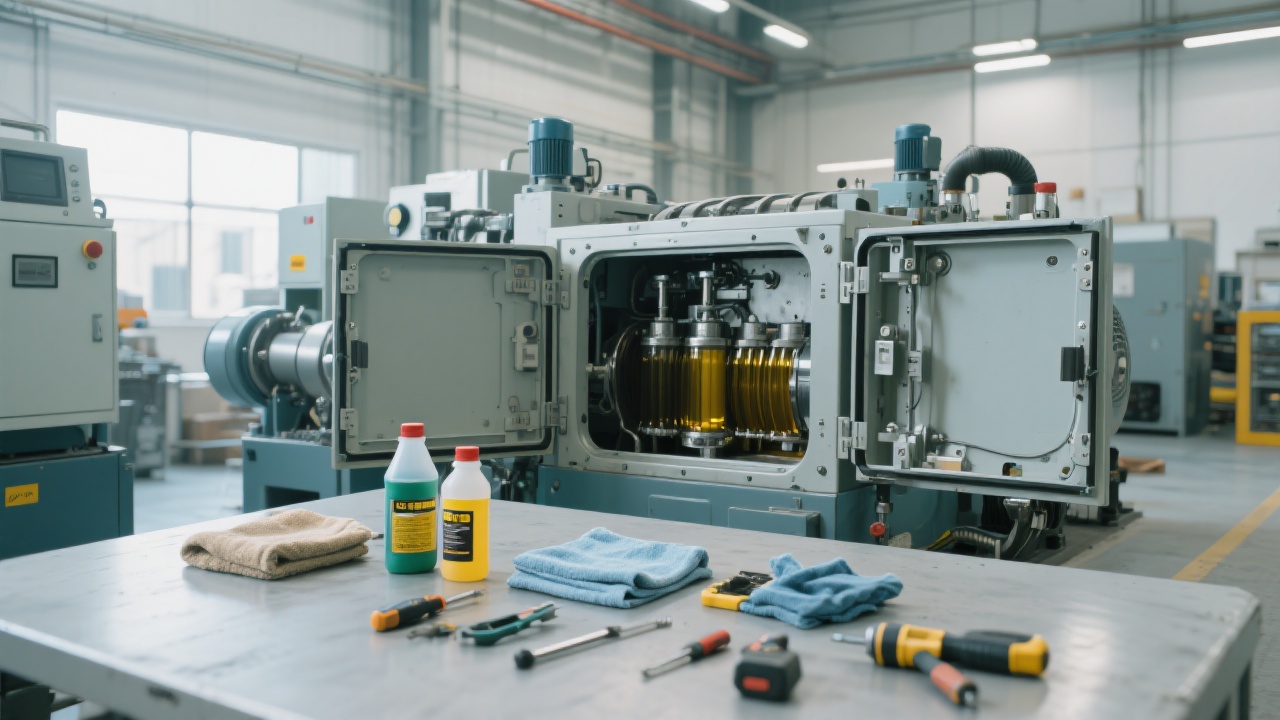

The fully enclosed system is the highlight of this sesame oil production line. The principle of this system is to isolate the production process from the external environment, preventing the entry of dust, microorganisms, and other contaminants. This system operates under a closed - loop mechanism. First, the raw materials enter the system through a sealed conveyor. Then, in the extraction and refining stages, all equipment is connected in a sealed manner. The steam and solvents used in the process are also recycled within the system, reducing waste and environmental pollution.

Compared with traditional open - type production systems, the fully enclosed system can significantly improve product quality. In a traditional system, the contamination rate of sesame oil can be as high as 5%, while in the fully enclosed system, the contamination rate is reduced to less than 1%. This ensures that the produced sesame oil has a longer shelf - life and a more pure flavor.

The sesame oil production equipment is designed with high efficiency in mind. It can produce up to 10 tons of high - quality sesame oil per day, which is suitable for both small - scale and large - scale production. In terms of energy consumption, the new equipment uses advanced energy - saving technology, reducing energy consumption by 30% compared to traditional equipment. Moreover, the operation of the equipment is very user - friendly. It is equipped with an intelligent control panel, which allows operators to easily set and adjust production parameters. Even inexperienced operators can quickly master the operation skills through simple training.

The company understands that different customers have different needs. Therefore, it provides customized solutions for global customers. For example, a small - scale food processing company in Africa requested a production line with a lower production capacity but high flexibility. The company designed a compact production line for them, which can produce different types of sesame oil products according to different market demands. For a large - scale food enterprise in Europe, which requires high - volume and fully automated production, the company provided a fully automated production line with advanced monitoring and control systems.

Many customers have given positive feedback on the sesame oil production line. A customer from the United States said, "The fully enclosed system ensures the high quality of the sesame oil we produce. Our sales have increased by 20% since we started using this production line." In addition, the production line has obtained multiple international certifications, such as ISO 9001 quality management system certification and HACCP food safety management system certification, which further enhances its credibility in the international market.

If you are interested in our high - quality sesame oil production line and want to learn more about how it can meet your specific needs, please click here to get in touch with us. We look forward to providing you with detailed information and customized solutions.