The global corn germ oil market is undergoing dynamic transformation driven by rising demand for healthy edible oils, evolving consumer preferences, and increasingly stringent environmental regulations. Corn germ oil, prized for its high nutritional value and favorable lipid profile, is experiencing a notable market expansion, particularly in key regions such as North America, Europe, and Asia-Pacific. Forecasted to grow at a compound annual growth rate (CAGR) of approximately 6.5% over the next five years, this sector is catalyzing technological innovation in processing and production lines that optimize energy consumption and product quality.

The corn germ oil industry is shaped by:

According to recent market analyses, environmentally sustainable production is no longer optional but decisive for competitive positioning, prompting manufacturers to prioritize innovation in their production lines.

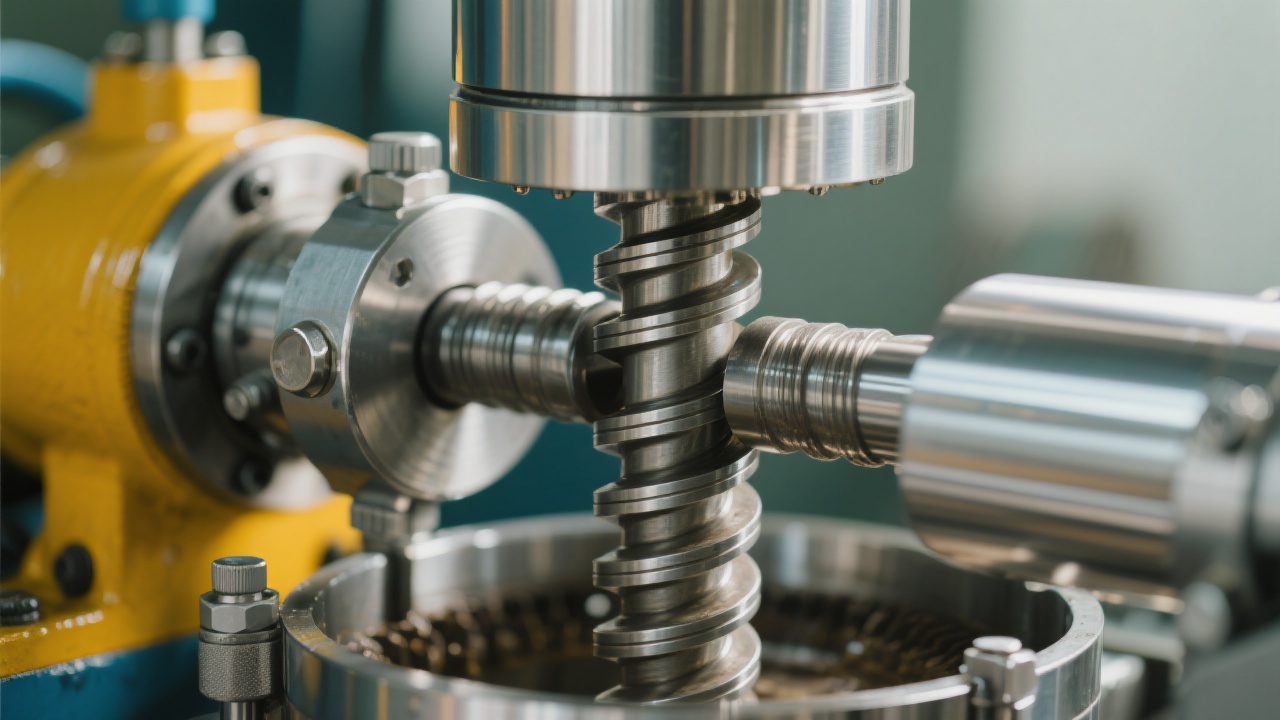

Leading-edge corn germ oil production lines integrate a range of technical advancements aimed at reducing energy consumption while ensuring stable, high-quality output:

| Core Technology | Benefits | Ecological Impact |

|---|---|---|

| Advanced solvent extraction coupled with precise temperature control | Maximizes oil yield by up to 5%, reduces solvent loss | Reduces VOC emissions by 20% |

| Energy recovery units integrated in the process flow | Decreases total energy demand by 30% | Lowers carbon footprint substantially |

| Real-time monitoring and automated control systems | Ensures consistent quality and rapid fault detection | Minimizes waste through precise operation |

Comparing industry-leading production lines highlights our company's distinct competitive advantages in key areas:

These features combined deliver measurable cost savings and reduced operational risk to grain oil processing enterprises and food manufacturers.

The trend towards modular setups revolutionizes scalability and adaptability in the corn germ oil sector:

These advantages contribute to better project budgeting and accelerate return on investment for customers.

For grain oil processing enterprises, agricultural cooperatives, and food manufacturers, selecting an ideal production line requires assessing multiple factors:

| Consideration | Impact | Recommended Focus |

|---|---|---|

| Energy Consumption | Directly affects operational expenses and eco-compliance | Prioritize lines with proven low kWh per ton oil extracted |

| Maintenance Requirements | Influences downtime and long-term reliability | Look for modular designs and automated diagnostics |

| Production Stability | Ensures consistent product quality and supply chain confidence | Select technologies validated by operational data |

These decision points, when carefully evaluated, empower businesses to secure capital-efficient investments with long-lasting competitive advantages.

Our commitment to client success extends beyond the point of sale with a robust, multi-tiered support framework:

This end-to-end partnership model supports sustainable production, risk mitigation, and maximizes return on investment.

In conclusion, the evolution and growth of the global corn germ oil market necessitate adoption of cutting-edge, energy-efficient production technologies. High-quality corn germ oil production lines featuring modular design, advanced automation, and superior energy management present clear advantages in reducing operational costs and environmental impact. For grain oil processors and food manufacturers striving to maintain competitiveness in a demanding marketplace, investing in these production assets translates to higher yields, improved product consistency, and compliance with sustainability standards. Our company's production lines not only meet but exceed these critical benchmarks, empowering clients to achieve resilience and growth in the global edible oil industry.