In today’s competitive global market, soybean oil producers face increasing demands for not only high-quality products but also sustainable and environmentally friendly manufacturing processes. Our company leverages advanced technologies and rigorous quality control throughout the entire soybean oil production chain—from raw soybean cleaning to final packaging—to deliver superior oils while ensuring zero waste through the full utilization of valuable by-products.

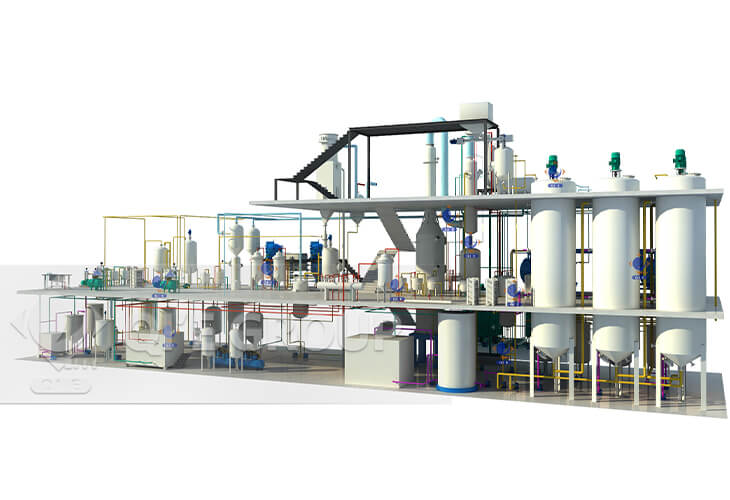

The journey begins with the thorough preparation and cleaning of raw soybeans, eliminating impurities and optimizing the raw material for processing. We employ state-of-the-art medium-sized screw oil press machines that efficiently extract oil while preserving nutritional value.

Once extracted, the crude oil undergoes refining stages including degumming, neutralization, bleaching, and deodorization—using sophisticated oil fractionation equipment—to ensure purity and an outstanding flavor profile. Each machine and process is monitored with precision instruments that guarantee consistency and adherence to international standards.

Our company continually invests in R&D to enhance production efficiency and oil quality. For instance, by integrating automated temperature and pressure controls within our refining units, we have reduced energy consumption by 12% while increasing oil yield rates by up to 3%. This not only contributes to cost savings but also aligns with global sustainability targets.

One of the greatest strengths in soybean oil production is its array of useful by-products, primarily soybean meal (or “soybean cake”) and lecithin, which help realize a zero-waste manufacturing philosophy.

| By-Product | Primary Uses | Environmental Benefits |

|---|---|---|

| Soybean Meal (Bean Cake) | High-protein animal feed, fertilizer | Reduces landfill waste and promotes circular economy |

| Lecithin (Phospholipids) | Food additives, cosmetics, pharmaceuticals | Enhances resource utilization efficiency |

For example, our soybean meal contains an impressive 48% protein content, making it a preferred choice for livestock and poultry nutrition worldwide. Simultaneously, the extracted lecithin is refined on-site to cater to various industries, ensuring every fraction of the soybean is exploited responsibly.

Across all production lines, our monthly soybean oil output exceeds 10,000 tons with an average oil extraction efficiency of 18.5%, outperforming industry averages by 2%. Our stringent quality control protocols encompass regular testing for free fatty acids, moisture, and impurity levels—all maintained below internationally mandated thresholds.

Sustainability isn’t just a buzzword here. With over 96% of soybean raw materials sourced through traceable and certified suppliers committed to eco-friendly farming practices, our production facility ensures minimal environmental impact. Energy recovery systems implemented at our refining units have cut carbon emissions by 15% year-over-year.

For global buyers seeking a reliable partner capable of delivering not only premium soybean oil but also showcasing an outstanding commitment to environmental stewardship and resource optimization, our scalable production capabilities and value-driven innovations stand unmatched.

Discover how partnering with us can elevate your supply chain with consistent quality, transparency, and sustainability.