In today's era, the grain and oil industry is facing increasing pressure to balance environmental protection and high - yield production. With the growing emphasis on sustainable development, both large - scale oil mills and emerging processing enterprises are seeking solutions that can reduce energy consumption while maintaining high - quality output. Traditional corn germ oil production lines often struggle with high energy consumption, unstable product quality, and high maintenance costs, which not only affect the economic benefits of enterprises but also go against the trend of green development.

Traditional corn germ oil production lines have several significant drawbacks. Firstly, in terms of energy consumption, they rely on outdated technologies that consume large amounts of electricity and heat energy. For example, the heating and cooling processes in traditional extraction methods are not well - optimized, resulting in a high unit energy consumption per ton of oil produced. Secondly, the stability of product quality is a major concern. Fluctuations in temperature, pressure, and other process parameters can lead to inconsistent oil quality, which is a big problem for brand building and market competitiveness. Thirdly, the maintenance of traditional production lines is complex and costly. The non - modular design makes it difficult to replace parts and upgrade the system, increasing the long - term operation cost of enterprises.

Our company's corn germ oil production line is designed to address these pain points. We have adopted a series of advanced energy - saving technologies, such as heat energy recovery and intelligent temperature control systems. The heat energy recovery system can capture and reuse the waste heat generated during the production process, reducing the overall energy input. For instance, the heat released during the oil refining process can be used to pre - heat the raw materials, which can save up to 30% of the energy consumption compared to traditional methods. The intelligent temperature control system can precisely adjust the temperature at each stage of the production process, ensuring the stability of oil quality and further reducing energy waste.

One of the key features of our production line is its modular design. This design concept brings many benefits. In terms of installation, the modular components can be quickly assembled on - site, significantly reducing the installation time and cost. For example, a traditional production line may take several weeks to install, while our modular production line can be up and running in just a few days. In terms of maintenance, the modular design allows for easy replacement of faulty parts, reducing the downtime of the production line. Moreover, it also provides flexibility for future expansion. Enterprises can easily add or upgrade modules according to their production needs, ensuring that the production line can adapt to market changes.

Compared with competitors, our corn germ oil production line has several core advantages. Firstly, in terms of product quality, our production line can ensure high - quality and consistent oil production. Through precise process control, the oil produced has a higher nutritional value and better taste. Secondly, our production line has a lower dependence on manual labor. The intelligent control system can automate most of the production processes, reducing the labor cost and human error. Thirdly, the operating cost is more controllable. With energy - saving technologies and modular design, the long - term operation cost of our production line is significantly lower than that of traditional and some competing production lines. For example, the energy - saving measures can reduce the energy cost by 30%, and the modular design can save up to 20% in maintenance cost.

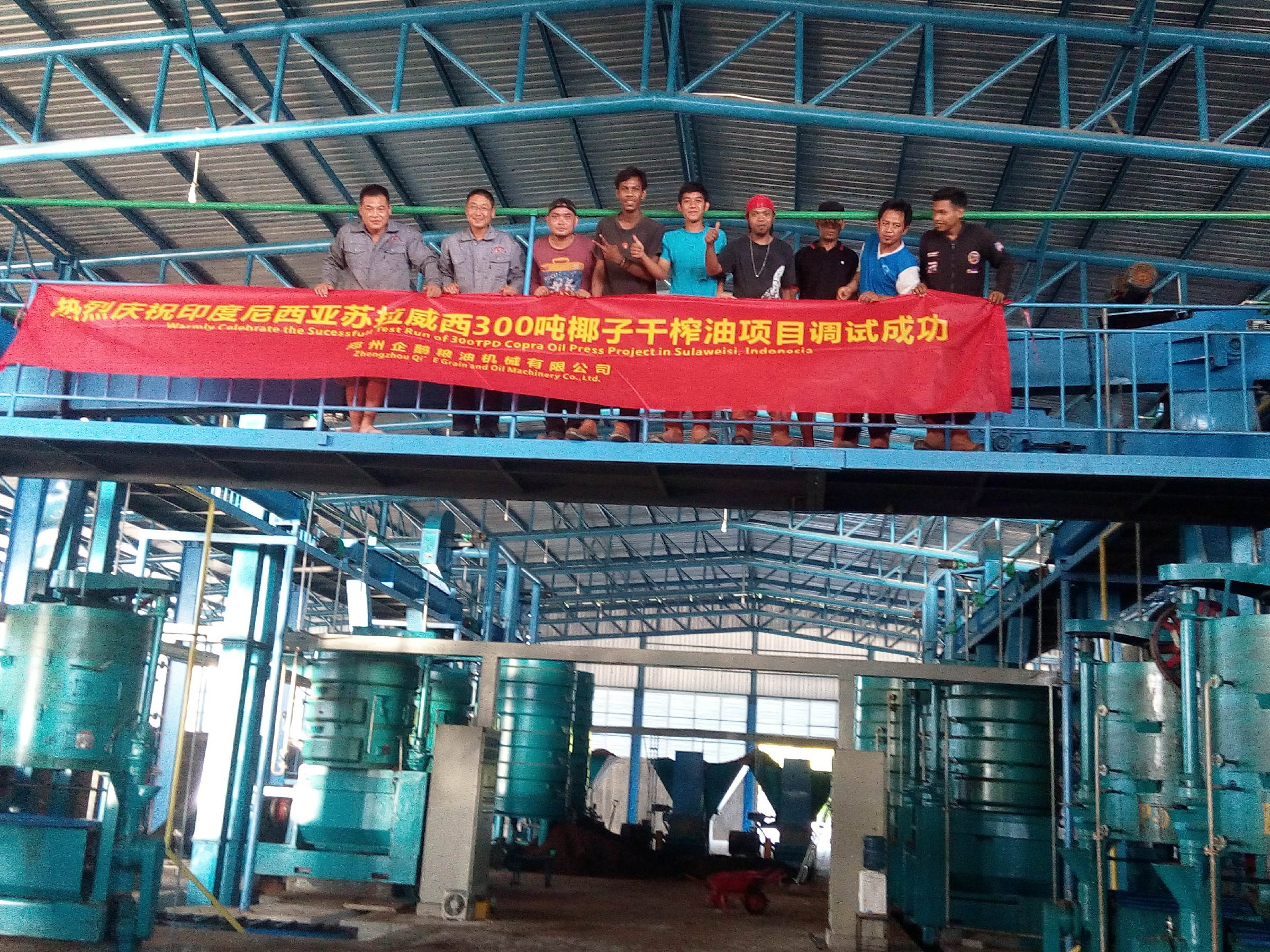

We have many real - world customer cases to prove the effectiveness of our production line. For example, a medium - sized oil mill in [Country Name] installed our corn germ oil production line. After one year of operation, they reported a 30% increase in energy - saving rate and a 20% increase in production capacity. The quality of their oil products has also been highly recognized in the market, which has helped them expand their market share. As one of our customers said in a testimonial, "This production line has truly changed our business. It has allowed us to achieve high - quality production with lower costs, making our products more competitive in the market."

In conclusion, our corn germ oil production line offers a comprehensive solution for the grain and oil industry. Whether you are a large - scale oil mill looking to upgrade your equipment or a startup processing enterprise aiming to enter the market with high - efficiency production, our production line can provide you with an efficient, environmentally - friendly, and easy - to - maintain solution. Let your oil mill start with an edge in efficiency and sustainability. Don't miss this opportunity to enhance your competitiveness in the market!

Explore Our Corn Germ Oil Production Line Now!