Have you ever wondered about the intricate process behind the production of soybean oil? In this article, we'll take you on a fascinating journey through every step of soybean oil production, from the moment the soybeans are received to the final packaging and sale. We'll also introduce the by - products and show you how our company ensures high - quality production with professional techniques and a commitment to environmental sustainability.

The first step in soybean oil production is the preparation and cleaning of soybeans. When the soybeans arrive at our facility, they may contain various impurities such as stones, dirt, and broken beans. We use advanced cleaning equipment, like vibrating screens and magnetic separators. The vibrating screen can separate larger impurities by size, while the magnetic separator removes any metal objects. According to our statistics, this initial cleaning process can remove up to 95% of the impurities, ensuring that only high - quality soybeans enter the next stage of production.

After cleaning, the soybeans are broken and dehulled. We use special crushers to break the soybeans into smaller pieces. This process not only makes it easier to extract the oil but also helps to separate the hulls from the soybean kernels. The hulls are then removed using aspirators. Dehulling is crucial because soybean hulls contain very little oil, and removing them can increase the oil - extraction efficiency. In fact, our dehulling process can increase the oil - extraction rate by about 2 - 3%.

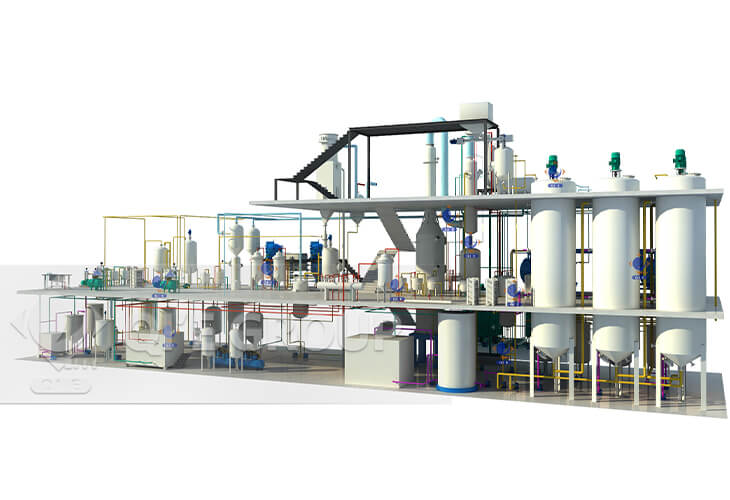

There are two main methods of oil extraction: mechanical pressing and solvent extraction. At our company, we combine these two methods to achieve the highest oil - extraction rate. First, we use mechanical presses to squeeze out a large portion of the oil. Then, the remaining oil in the soybean meal is extracted using solvents. Our state - of - the - art extraction equipment can extract up to 98% of the oil from the soybeans. The extracted crude oil is then sent for refining.

The refining process is essential to remove impurities, odors, and colors from the crude oil. It includes several steps such as degumming, neutralization, bleaching, and deodorization. Our company uses advanced refining technology to ensure that the final soybean oil meets the highest quality standards. For example, the bleaching process can reduce the color of the oil to a very low level, making it more appealing to consumers. After refining, the soybean oil is clear, odorless, and has a long shelf - life.

In addition to soybean oil, our production process also generates valuable by - products. The soybean meal left after oil extraction is a high - quality protein source, widely used in animal feed. We also recycle the hulls, which can be used as bedding for livestock or as a raw material in the production of bio - fuel. This full utilization of resources not only reduces waste but also reflects our commitment to environmental protection and sustainable development.

Throughout the entire production process, our company adheres to strict quality control measures. We have a professional quality control team that monitors every step, from raw material inspection to the final product testing. Our advanced testing equipment can detect even the slightest impurities or quality issues, ensuring that only the best - quality soybean oil reaches the market. This strict quality control, combined with our professional production techniques, has earned us a high reputation in the industry.

In conclusion, soybean oil production is a complex yet fascinating process. Our company is dedicated to producing high - quality soybean oil with advanced technology and a focus on environmental sustainability. We invite you to partner with us and experience the excellence of our soybean oil products.

Contact us today and discover how our professional production and strict quality control can meet your needs. Let's build a successful partnership together!